What is a Cross-Connection?

A cross-connection is any physical connection between a public or consumer’s water system and any source of non-potable liquid, solid, or gas that could contaminate the potable water supply by backflow.

What Is Backflow?

Backflow is the undesirable reversal of the flow of water from its intended direction in a pipeline or plumbing system. It can result from a loss of pressure in the public water system (for example, due to a large leak), which can in turn draw non-potable water from the customer’s property (fire sprinkler systems, irrigation systems, hot tubs, etc.) into the public water system at unprotected cross-connections. Prevention of backflow at cross-connections (“cross-connection control”) is critical to protecting public health.

There are two types of backflow: backsiphonage or backpressure.

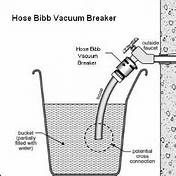

- Backsiphonage may occur due to a loss of pressure in the water distribution system during a high withdrawal of water for fire protection, water main or plumbing system break, or shutdown of a water main or plumbing system for repair. A reduction of pressure below atmospheric pressure creates a vacuum in the piping. If a hose bib was open and the hose was submerged in a wading pool during these conditions, the non-potable water in the pool could be siphoned into the home’s plumbing and back into the public water system.

- Backpressure may be created when a source of pressure, such as a pump, creates a pressure greater than that supplied from the distribution system. If a pump supplied from a non-potable water source, such as a landscape pond, were accidentally connected to the plumbing system, the non-potable water could be pumped into the potable water supply.

Where are Cross-Connections?

Cross-connections are found in all plumbing systems. It is important that each cross-connection be identified and evaluated to determine the type of backflow protection required to protect the drinking water supply. Some plumbing fixtures have built-in backflow protection in the form of a physical air gap. However, most cross-connections will need to be controlled through the installation of an approved mechanical backflow prevention device or assembly.

Some of the most common customer cross-connection hazards include:

- Irrigation sprinkler systems

- Solar heat systems

- Wash basins and service sinks

- Hose bibs/faucets/outside spigots

- Auxiliary water supply (wells, catchment systems)

- Laboratory and aspirator equipment

- Photo developing equipment

- Processing tanks

- Boilers

- Water recirculation systems

- Pools/hot tubs/decorative ponds

What Am I Responsible For?

Irrigation/Fire system without chemicals backflow protection

Per WAC# 246-290-490, property and business owners are required to install and maintain backflow prevention assemblies where they are needed. WWSC customers are also responsible for having their backflow assemblies tested annually by a State Certified Tester.

About Backflow Assemblies

A backflow assembly is a mechanical device required by law to protect public health and is installed on a customer’s property to prevent contamination from entering the potable water supply. Common types of assemblies include:

Auxiliary source of supply/radiant floor heating system connected to water supply backflow protection

Double Check Valve Assembly (DCVA)

- The DCVA may be installed to isolate all irrigation systems that do not use injectors or pumps to apply fertilizer and other agricultural chemicals

- The DCVA may be installed in an underground enclosure provided the assembly test cocks are plugged, the test cocks are pointed up, adequate space is provided for maintenance and testing, and any compressed air connections are installed only downstream of the DCVA.

- The DCVA must be tested by a certified backflow assembly tester upon installation, after repair or relocation, and at least annually.

Reduced Pressure Backflow Assembly (RPBA)

- The RPBA should be installed to isolate irrigation systems using injectors or pumps that apply fertilizer and other agricultural chemicals.

- The RPBA must be installed 12″ above ground to prevent the relief valve opening from becoming submerged.

- The RPBA must be installed in an insulated enclosure to provide freeze protection.

- The RPBA must be tested by a certified backflow assembly tester upon installation, after repair or relocation, and at least annually.

Pressure Vacuum Breaker (PVB)

- Hose connection vacuum breakers are specifically made for portable hoses attached to hose thread faucets. Their purpose is to prevent the flow of contaminated water back into the drinking water. These devices screw directly to the faucet outlet. They can be used on a wide variety of installations, such as service sinks, hose faucets near a wading pool, laundry tub faucets, etc.

- Some units are designed for manual draining for freezing conditions. Some are furnished with breakaway set screws as a tamper-proof feature.

- These devices are not intended for operation under continuous pressure.

Where Is a Backflow Assembly Required?

A backflow assembly is required wherever there is a possibility of a cross-connection between the public water system and a non-potable water source. Examples include, but are not limited to, irrigation systems, boilers, hot tubs, and other water-using equipment.

Some states require mandatory backflow protection on certain facilities where high health hazard-type cross-connections are normally found. The following is a partial list of those facilities:

- Hospitals, mortuaries, and clinics

- Laboratories

- Food and beverage processors

- Metal plating and chemical plants

- Car washes

- Petroleum processing and storage plants

- Radioactive processing plants and nuclear reactors

- Piers and docks

- Sewage treatment plants

Find a Certified Tester

Visit Washington Certification Services for a list of certified Backflow Assembly Testers (BAT) by county, or see our list of testers.

What Will Happen If I Do Not Have My Backflow Assembly Tested?

The law requires that your backflow assembly be tested annually to ensure that it is working properly and to protect public health. Failure to test the assembly increases the risk that it will fail to protect the water supply. WWSC will mail reminder notifications about backflow assembly testing requirements to you annually. However, please be aware that it is the customer’s responsibility to ensure that the assemblies are tested on time. If an assembly is not tested, WWSC will take action, starting with assessing fees and leading to termination of water service.

WWSC will make every effort to work with the customer to avoid these actions from being taken, but WWSC must imperatively ensure that the drinking water system is protected.

A Reminder About Outdoor Faucets

Everyday things you do when using an outdoor faucet can put you and your family at risk. If an outdoor faucet is in contact (directly or via a hose) with dirty water and there is an unexpected change in pressure, that water can be sucked back into your home’s drinking water pipes.

Tips To Prevent Outdoor Faucet Backflow

The easiest and best way to protect your family is to install vacuum breakers on all outdoor faucets. Vacuum breakers completely prevent backflow through outdoor faucets and are available at all major home improvement stores for around $5 each. All Homes built in 1996 and after per plumbing code, already have vacuum breakers on outdoor faucets.

If you choose not to install vacuum breakers make sure you:

- Never leave a hose submerged in a bucket of water — submerging briefly can make a big difference

- Hold hoses above the water line when filling pools, hot tubs, etc.

- Do not use fertilizer sprayers

|

|

| Hose Bib Vacuum Breaker | |

Information for Testers

See the Backflow Assembly Test Guidelines page for our standardized testing report form, requirements, and instructions on how to submit test reports.